OUR SELF-CONVENIENCE

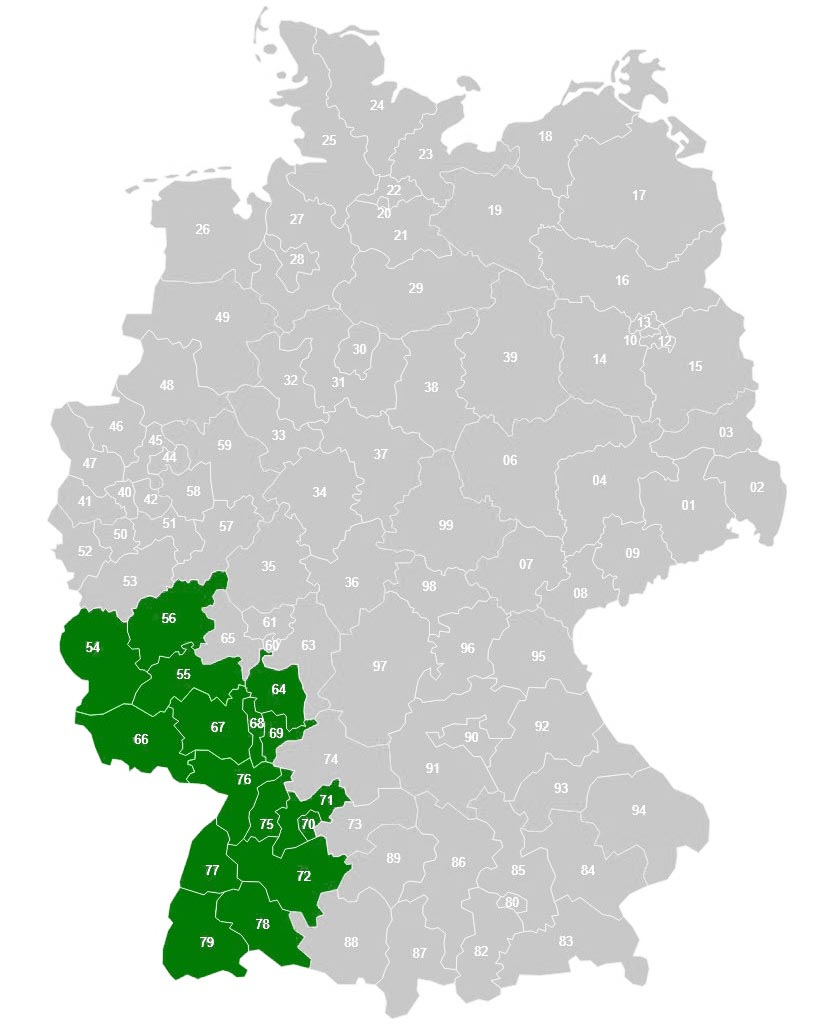

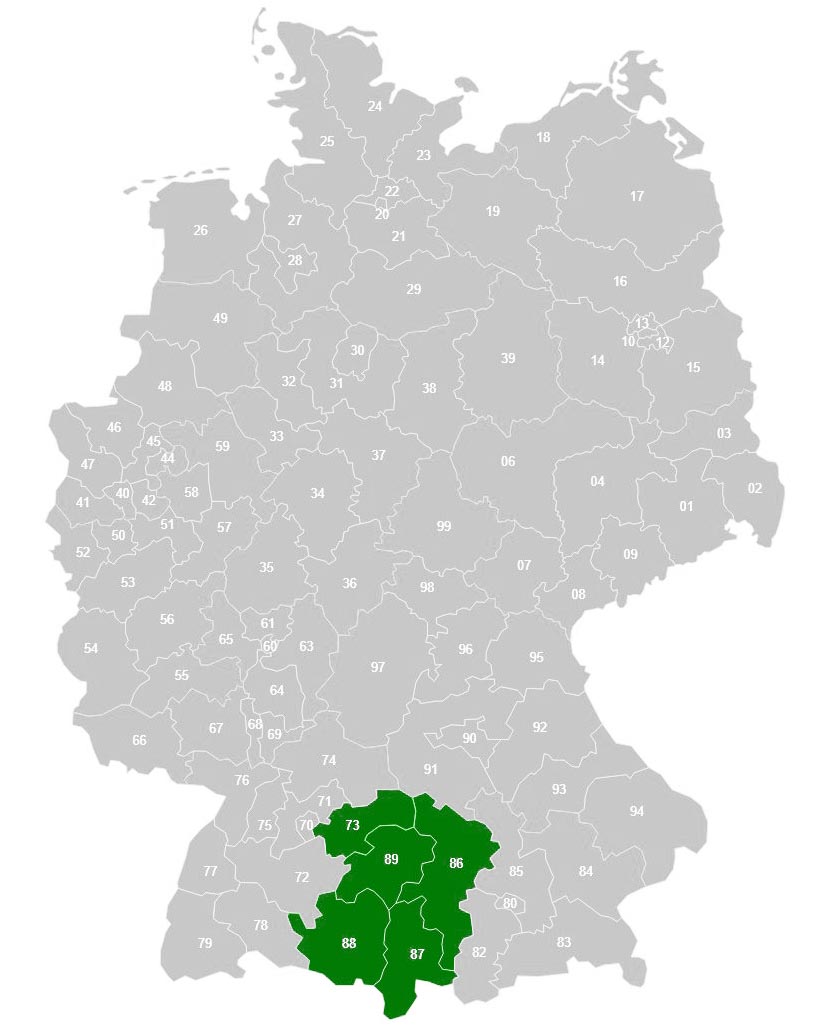

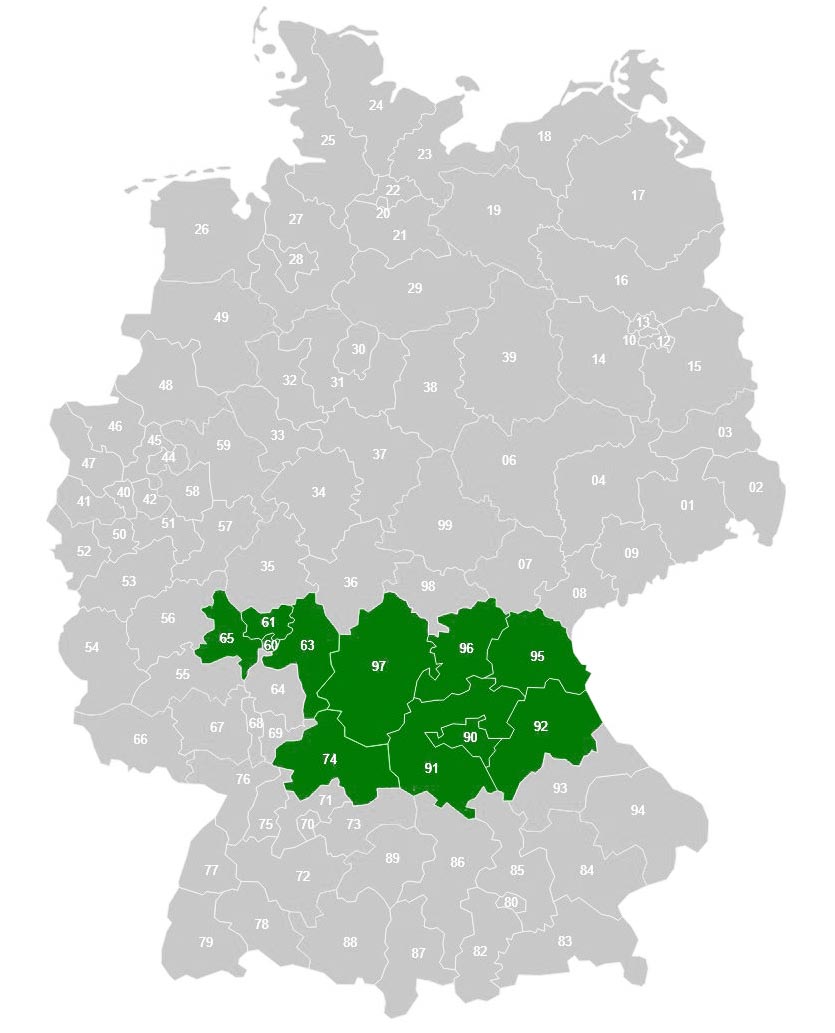

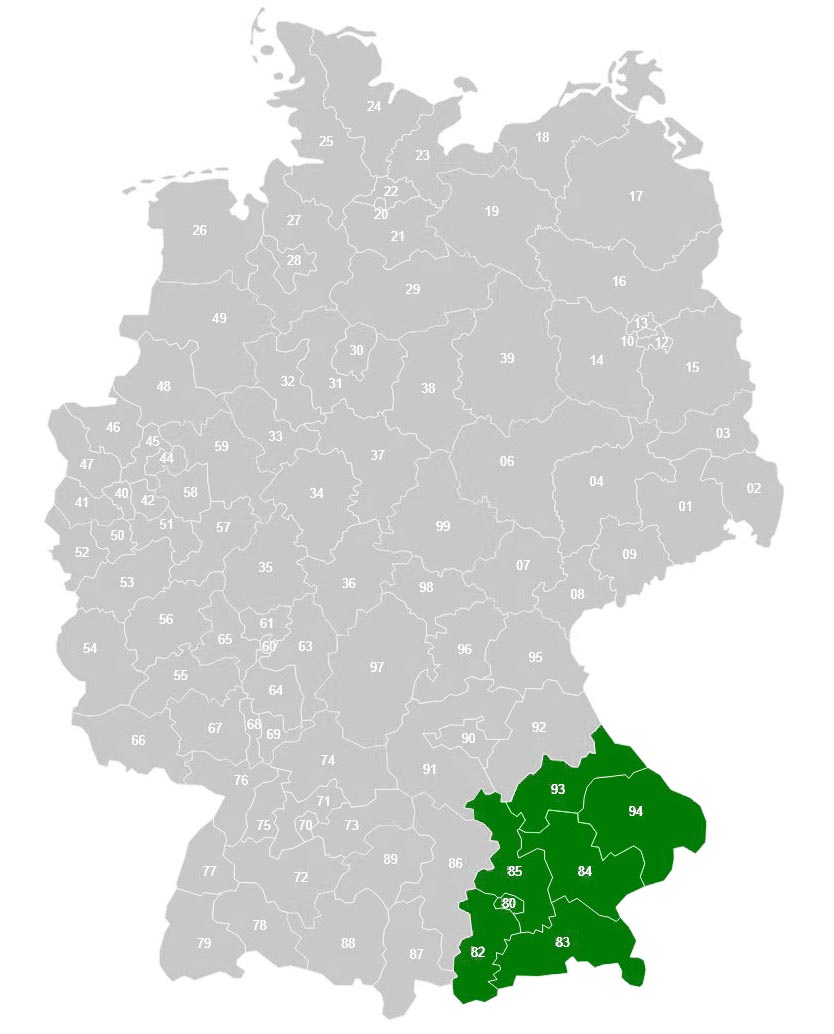

Many roads and roads increasingly suffer from the impacts of climate and traffic, which can, over time, lead to a fatigue and wear process as well as destruction. This process is to be counteracted by suitable repair and sanitation measures, so that the structural preservation is influenced in such a way that the requirements of safety and order are satisfied. The Süddeutsche Teerindustrie GmbH & amp; Co. KG has been dealing with technologies for perfect road maintenance for more than 107 years. Countless developments, which are “thoroughly tested” in our own lab, are a testament to high quality for upcoming measures. Customers from the entire Federal Republic of Germany, as well as from the European neighboring countries, rely on the experienced employees and the excellent products. STM stands for a fair partnership with maximum performance for our customers.

OUR VEHICLES

When we saw our vehicle fleet for the first time, we were astonished, but at the same time highly motivated, because all these “instruments” serve to meet your requirements.

With this overview, we want you to be able to decide what you want to accomplish everything together with us. The “Handwerkzeug” must be correct and in order.

Combined with qualified personnel and high-quality products, this achieves what you can expect from us for over 100 years. To be able to meet them is our drive, for years and for the future.

![fahrzeuge-rampe[1]](https://www.stm-malsch.de/wp-content/uploads/2018/08/Rampe-3.jpg)

![fahrzeuge-auflieger[1]](https://www.stm-malsch.de/wp-content/uploads/2016/06/fahrzeuge-auflieger1.png)

![fahrzeuge-service[1]](https://www.stm-malsch.de/wp-content/uploads/2016/06/fahrzeuge-service1.png)

![fahrzeuge-walze[1]](https://www.stm-malsch.de/wp-content/uploads/2016/06/fahrzeuge-walze1.png)

![fahrzeuge-man[1]](https://www.stm-malsch.de/wp-content/uploads/2016/06/fahrzeuge-man1.png)